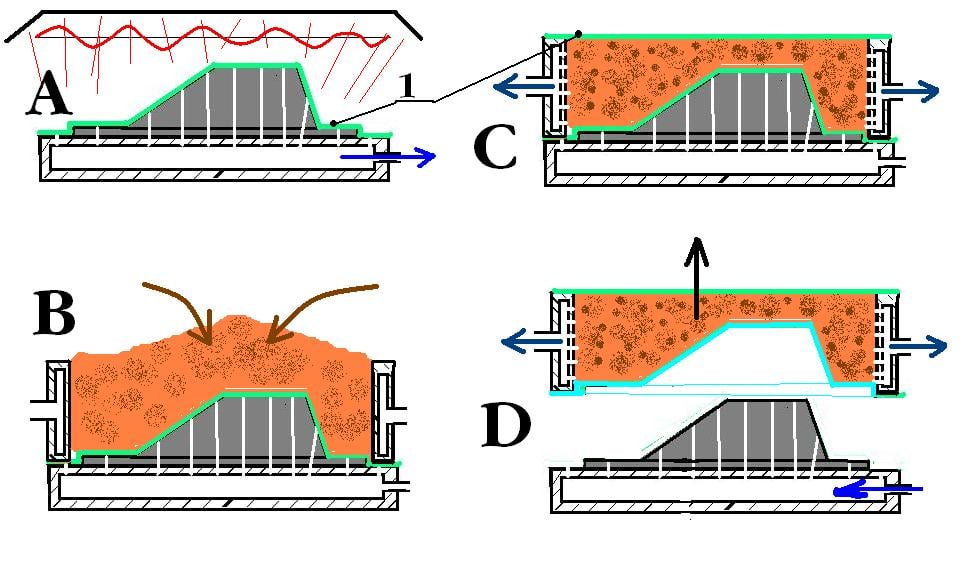

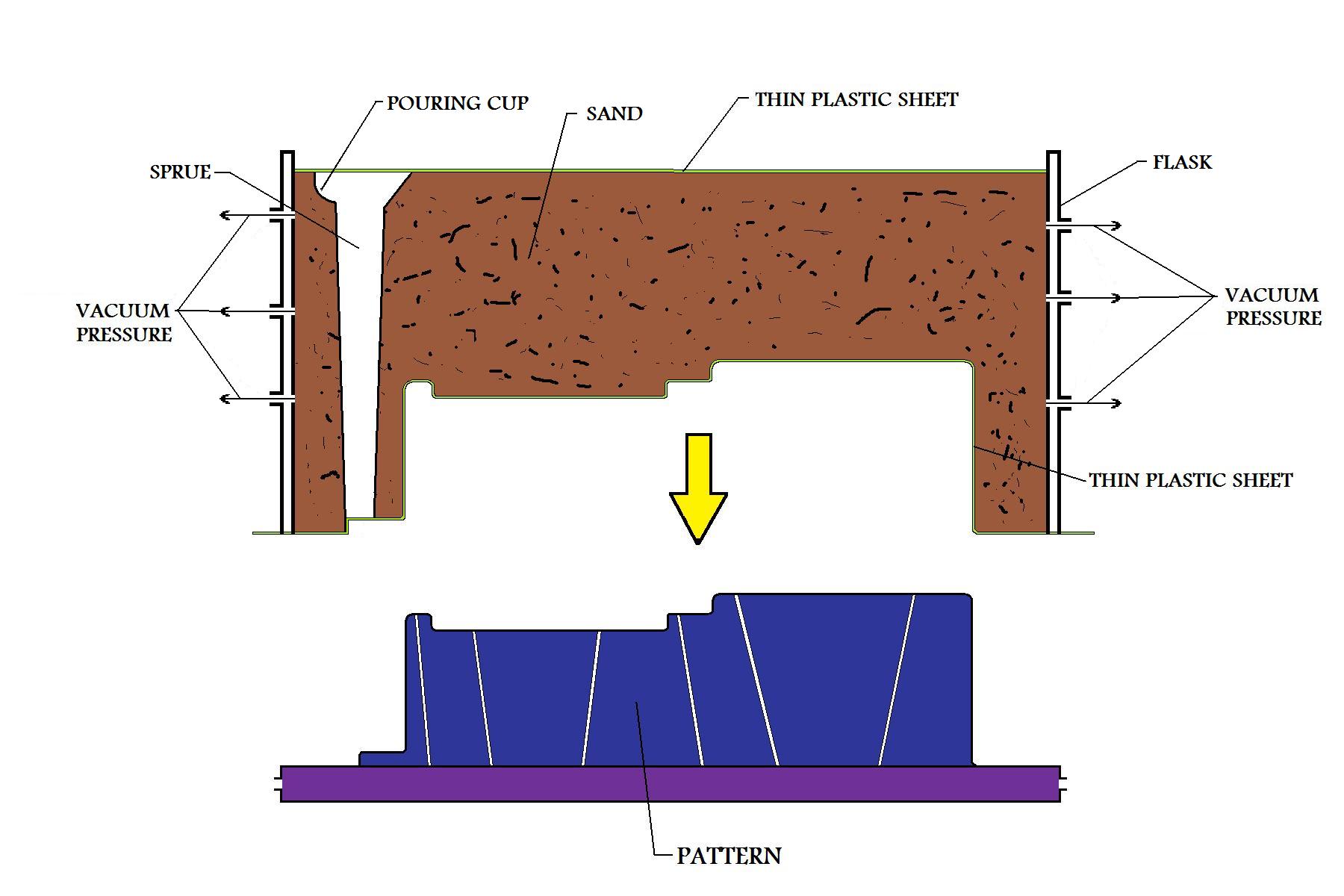

vacuum moulding process - Vacuum molding is a copying technique used to create a small series of functional plastic parts The process involves using two component polyurethanes and silicone molds for fast production of high quality prototypes or end use products

Vacuum forming is a plastic manufacturing process that involves using a machine to heat a plastic polymer till it is pliable before pulling it over a mold It is an important process in the low volume production of plastic parts The process is compatible with thermoplastics and thermoset materials despite their differences

vacuum moulding process

vacuum moulding process

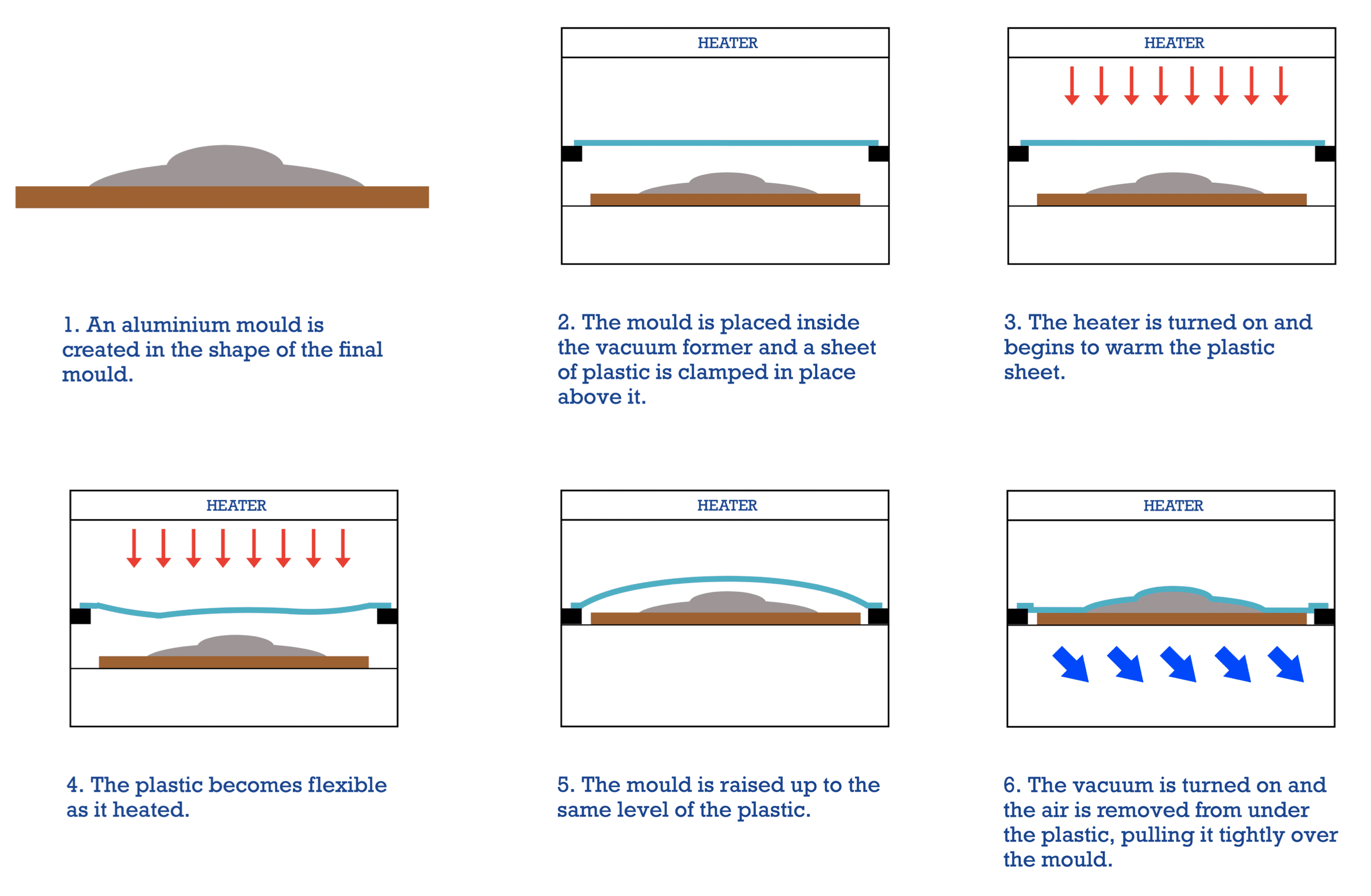

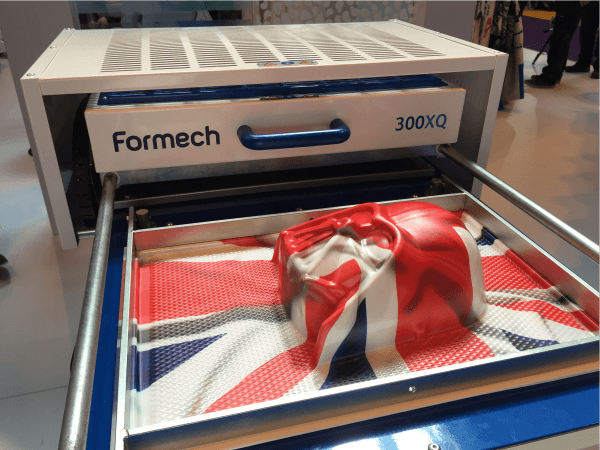

Vacuum forming is a simplified version of thermoforming, where a sheet of plastic (in various forms HIPS (High impact polystyrene) for low impact products, or for Bathroom shower trays ABS, and exterior vehicle parts HDPE, plus various other types of vacuum formable materials) is heated to a forming temperature, stretched onto a single-surface m.

An overview of the vacuum forming process How to create molds for vacuum forming The benefits and limitations of vacuum forming How vacuum forming is used both commercially and independently A short case study on vacuum forming and 3D printing

Vacuum Forming What Is It And How It Works WayKen

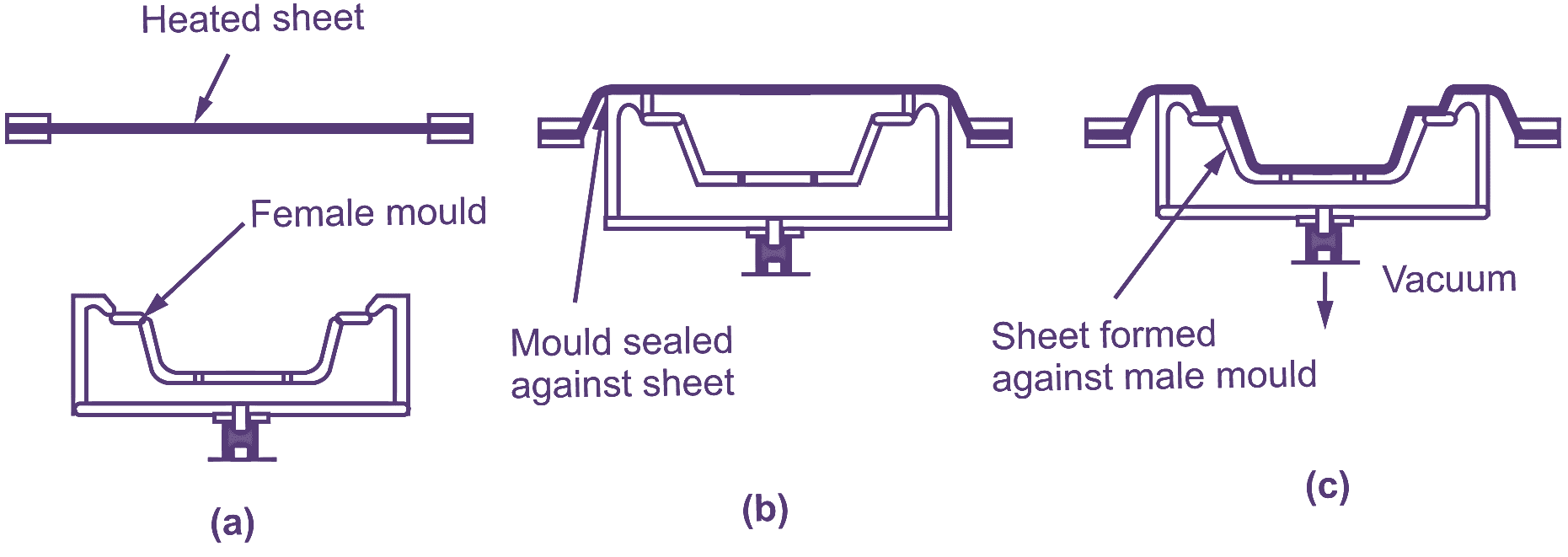

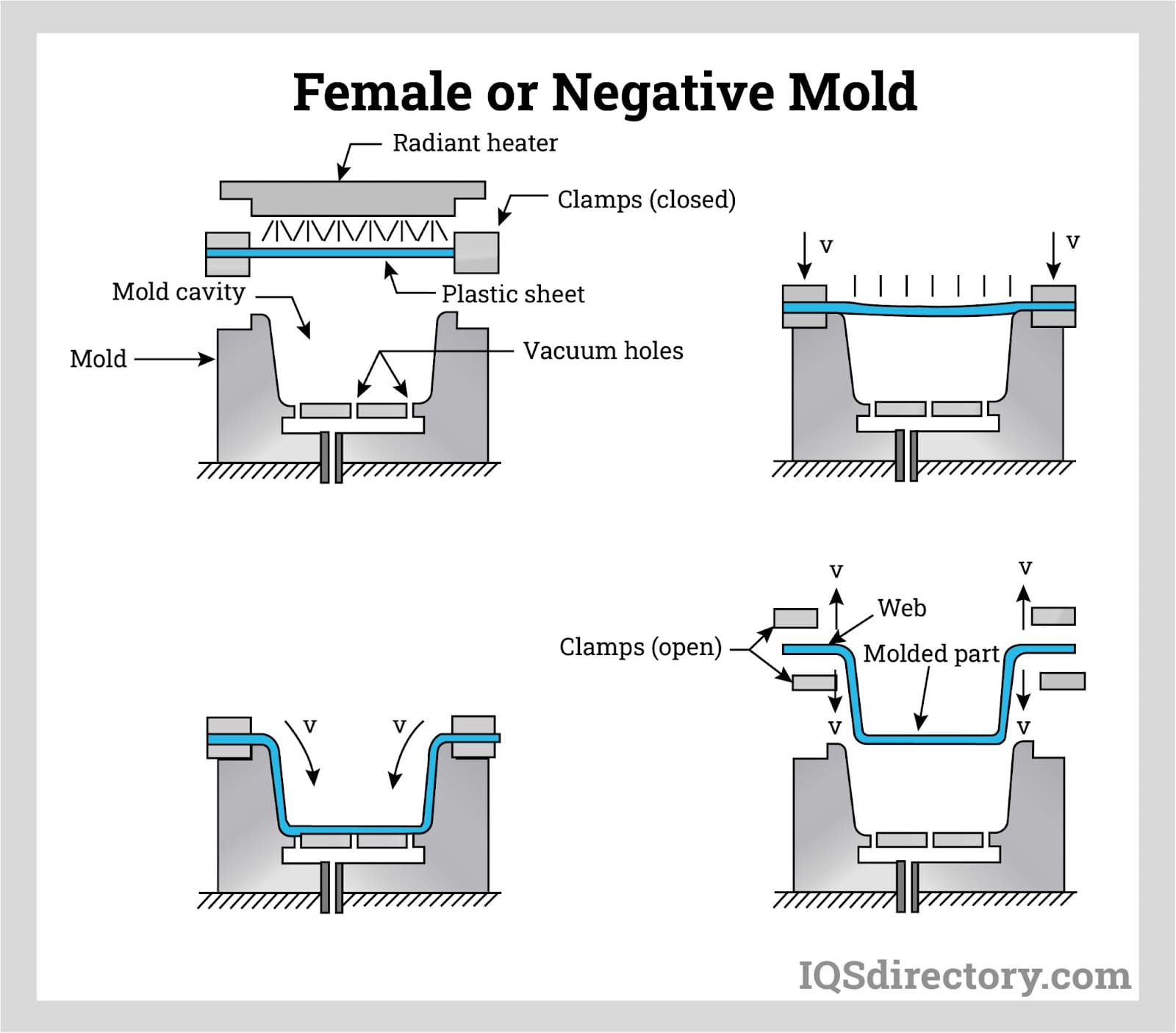

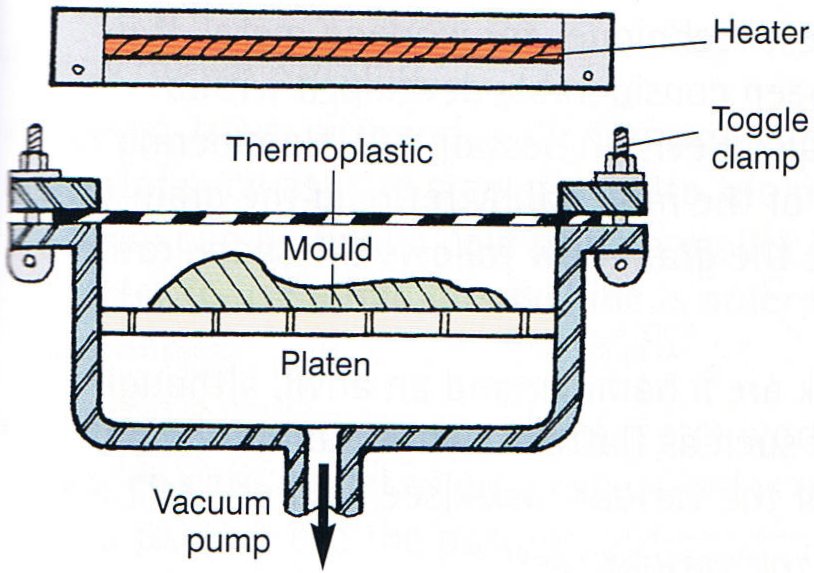

The vacuum forming process works by heating a plastic sheet forming it into a shaped vacuum forming tool using vacuum cooling the plastic sheet until it sets hard then removing the part from the tool Below the full process is

Cut Sheet Thermoforming Uses Which Type Of Clamping System

Vacuum forming also known as heat forming is a process that utilizes heat and vacuum pressure to shape plastic sheets into specific forms The process begins with a mold design which determines the shape and dimensions of the final product The plastic sheet is then heated until it becomes pliable and it is placed over the mold

Vacuum Forming Types Uses Features And Benefits

Sand Casting Vacuum Molding V Process Engineers Edge Www

How Does The Vacuum Molding Process Work Prototech Asia

22 Nov Vacuum forming The Vacuum Forming Process This is the process of moulding extruded plastic sheets heated to a pre determined temperature The sheets are heated and then sucked down by applying a vacuum to the underside of the mould atmospheric air pressure then forces the heated plastic to adopt the shape of the

Vacuum Molding Expandable Mold Casting Processes YouTube

Vacuum forming is a manufacturing process that produces shaped plastic products by heating a sheet of plastic and using vacuum suction to pull it around a mold The process uses various types of plastic such as polyethylene PE polycarbonate PC acrylonitrile butadiene styrene ABS and polyvinyl chloride PVC

[desc_10]

Vacuum Forming Wikipedia

The Vacuum Casting Process A Step by Step Guide The key element of vacuum casting is the silicone mold However there are some preliminary and post molding steps involved in making and use of silicone mold Here s a brief look at all those steps Step 1 Creating the Master Model First prepare a master mold to make that

How To Vacuum Form Plastic Mouldings Northern

Design Futures The Vacuum Forming Process

vacuum moulding process

Vacuum forming is a manufacturing process that produces shaped plastic products by heating a sheet of plastic and using vacuum suction to pull it around a mold The process uses various types of plastic such as polyethylene PE polycarbonate PC acrylonitrile butadiene styrene ABS and polyvinyl chloride PVC

Vacuum forming is a plastic manufacturing process that involves using a machine to heat a plastic polymer till it is pliable before pulling it over a mold It is an important process in the low volume production of plastic parts The process is compatible with thermoplastics and thermoset materials despite their differences

What Is Vacuum Moulding Dienamics

Vacuum Casting Or V process

Vacuum Forming What Is It And How It Works WayKen

Vacuum Forming Services Plastic Vacuum Forming Thermoplastic

What Are The Stages Of Vacuum Forming