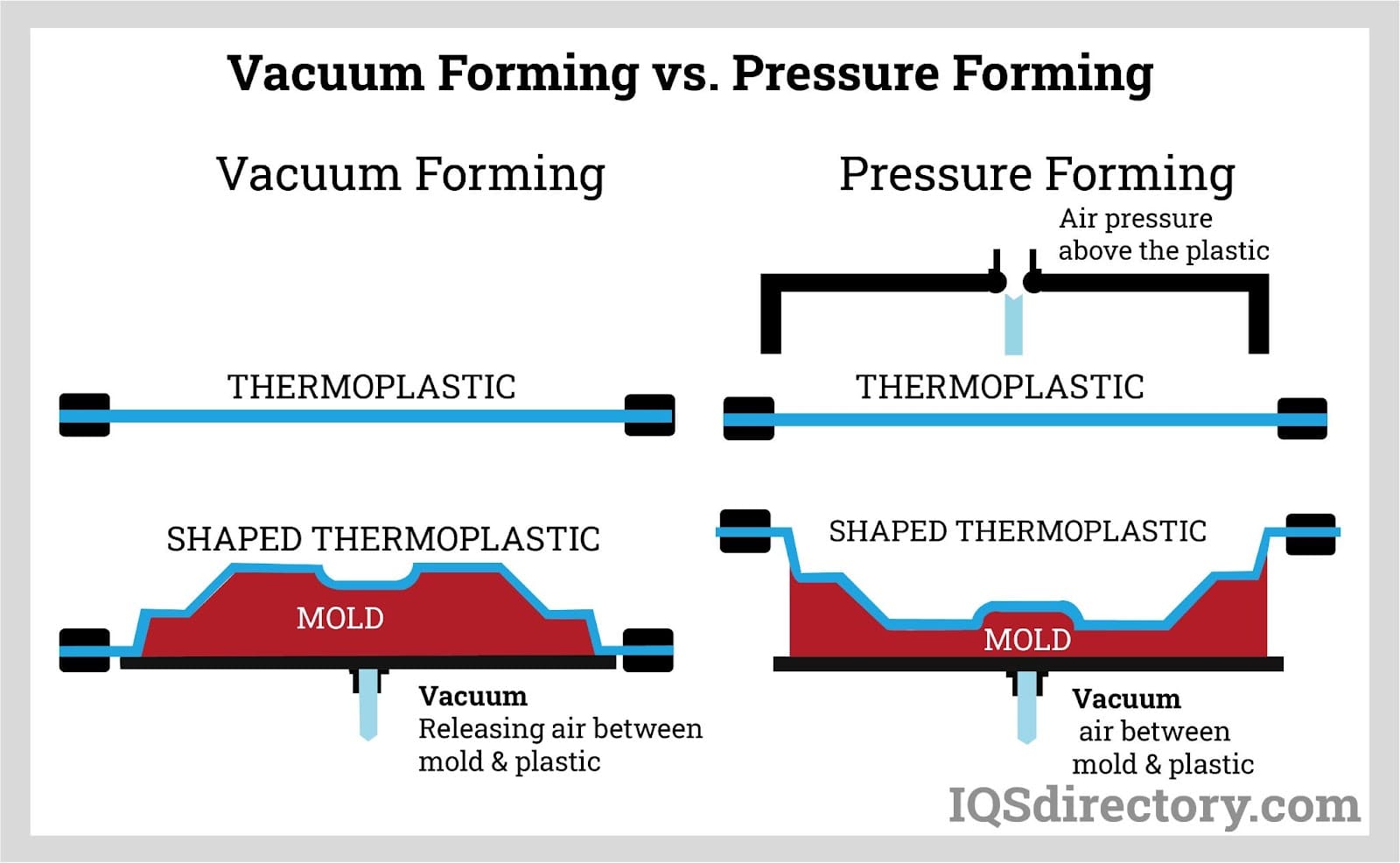

Vacuum Forming Vs Injection Molding - Vacuum forming and injection molding can be used to make many complex designs but there are many differences that start with cost production time raw material and details of a product for which you should take a detailed look at both processes Also Read Vacuum Forming Process Materials Benefit What is injection molding

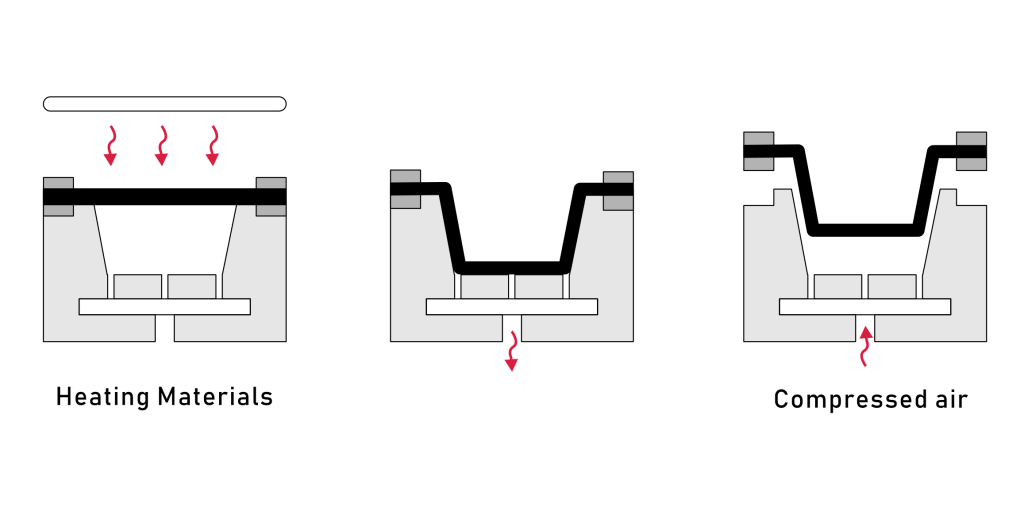

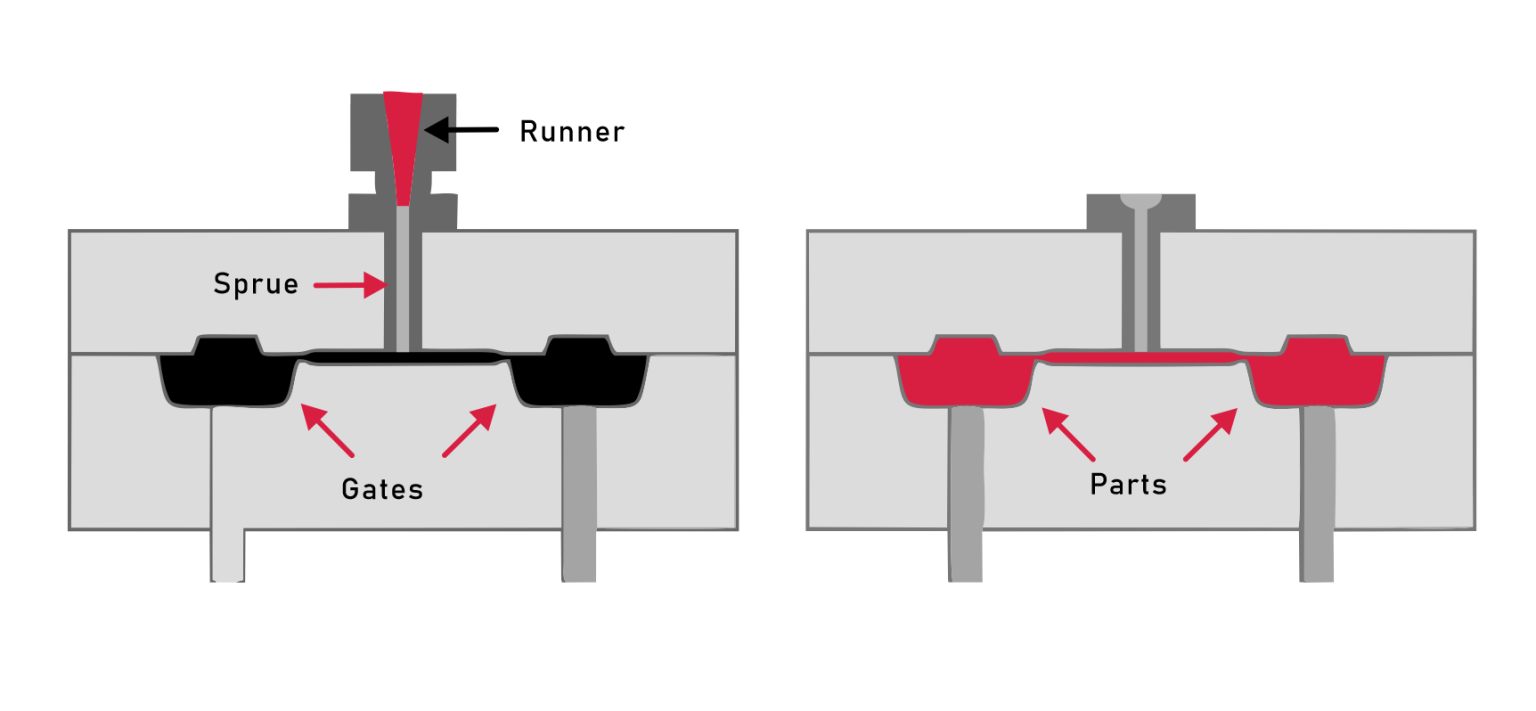

Injection moulding is a way of making plastic parts by melting the plastic material and injecting this into an injection mould tool For more detail have a look at our schematic overview of the injection moulding process or watch our screwthread injection moulding video to see it in action What is vacuum forming

Vacuum Forming Vs Injection Molding

Vacuum Forming Vs Injection Molding

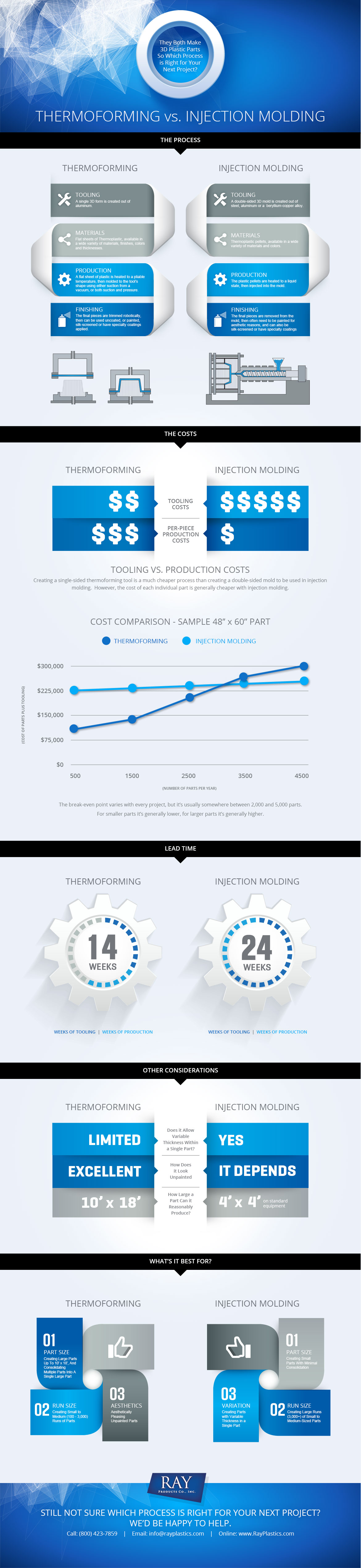

Vacuum Forming vs. Injection Molding: Comparing Techniques. In the vast world of manufacturing, different processes and techniques are utilized to produce a diverse range of products. Two such significant processes are vacuum forming and injection molding. While both serve the fundamental purpose of creating objects, the methodology, costs ...

Advantages Low cost for tooling and setup Can create large shallow parts with uniform thickness Quick turnaround time for low volume production runs Disadvantages Limited design flexibility compared to injection moulding Not suitable for some geometric shapes and complex parts Limited material options compared to injection moulding

Injection Moulding Vs Vacuum Forming Toolcraft

Comparison of Key Differences Closing Summary Injection molding and vacuum forming are versatile manufacturing techniques that are used to make a variety of lightweight durable plastic products and parts Both methods involve the use of molds require extreme heat and are overall very cost effective

Thermoforming Vs Injection Molding Ray Products

Vacuum Forming vs Injection Molding A Comparative Study Last updated July 7 2023 I Introduction The manufacturing world thrives on the ability to produce high quality uniform products in large quantities To achieve this several different manufacturing processes have been developed over the years

Vacuum Forming V Injection Moulding

Injection Molding Vs Vacuum Forming Alpine Mold

Vacuum Forming Vs Injection Molding What Is Difference

Plastic Injection Molding Vs Vacuum Forming What are the advantages and disadvantages of plastic injection molding and vacuum forming Both Form Plastic Using Different Methods Vacuum Forming Has Its Drawbacks Plastic Injection Molding Is The Optimal Plastic Forming Method

Vacuum Forming VS Injection Molding 101 Thermoforming Molds Solid Surface Molds Prestige

Vacuum forming is ideal for producing simpler designs with more basic geometries such as packaging trays and blister packs etc When it comes to choosing between injection molding and vacuum forming there are certain scenarios when injection molding is the superior process

Injection molding. Compared to vacuum forming, plastic injection molding is a more intricate manufacturing technique and requires a great degree of engineering expertise. The process initiates by heating polymers into a molten form. Usually made of aluminum or steel, this liquid polymer is then injected into a mold and held in place.

Vacuum Forming Vs Injection Molding Comparing Techniques

While vacuum forming often results in excess material from the trimmed plastic sheets injection molding might produce runners and sprues that are discarded unless reused Material Usage Injection molding tends to use more consistent and sometimes less material since the mold dictates the amount needed leading to consistent wall thickness

Thermoforming Vs Injection Molding Seaskymedical

Vacuum Forming Vs Injection Molding What Is Difference

Vacuum Forming Vs Injection Molding

Vacuum forming is ideal for producing simpler designs with more basic geometries such as packaging trays and blister packs etc When it comes to choosing between injection molding and vacuum forming there are certain scenarios when injection molding is the superior process

Injection moulding is a way of making plastic parts by melting the plastic material and injecting this into an injection mould tool For more detail have a look at our schematic overview of the injection moulding process or watch our screwthread injection moulding video to see it in action What is vacuum forming

Vacuum Forming Vs Injection Molding What Is Difference

Vacuum Injection Molding Material Google Suche Suche

Vacuum Forming Vs Injection Molding China MDE Plastics Company

Types Uses Features And Benefits 2022

Plastic Injection Molding Vs Vacuum Forming Richfields Blog